Harrison Rods – Made in the UK

Innovation, Quality and Performance

No 1 for Exceptional Carp Rods

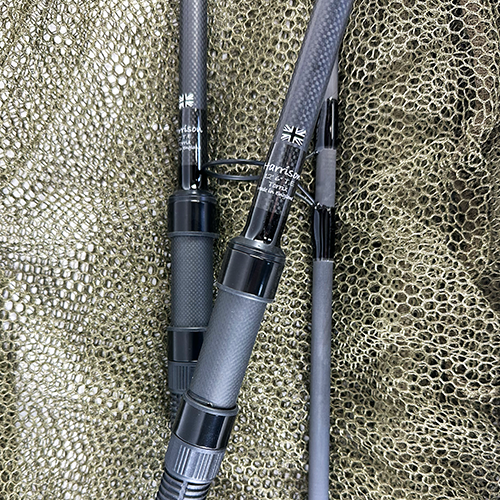

Aviator – Torrix – Acurix – Ballista – Trebuchet – Lorhic – GTi

“The pleasures of fishing are chiefly to be found in rivers, lakes and tackle shops and of the three, the last are the least effected by the weather. ” Arthur Ransome

Introducing the Harrison rod range

Explore the Best Carp Rods

Harrison Rods range explained.

Quick Link to Stockists

Quick Link takes you to our dealer page

Custom Built Harrison Rods

Endless Rod Customisation

Distance Carp Rods

Record breaking rods, Trebuchet UFR, Aviator TE

Aviator Carp Rod Range

Our premium carp rod range

Torrix Carp The Legend

Which Torrix rod build is for you?

Harrison Specialist Fishing Rods - the best of British

Harrison's also make tubes

We make canoe paddles, yacht tillers, spinnaker poles, and a wide range of tubes. Give us a call.

+44 (0)151 709 5981

info@harrisonrods.co.,uk

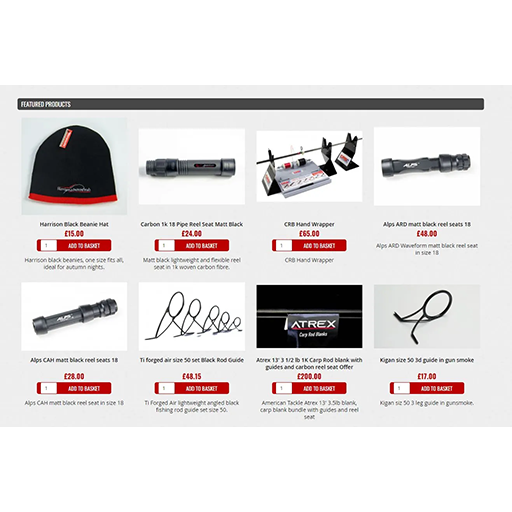

Harrison Rod building components

To cater for both the professional rod builder and hobbyists we offer a wide range of components. Some we make ourselves, some we select from the top coponents makers like American Tackle, Kigan and Alps.

Harrison Rod Blanks Direct

We do not sell rods direct but you can buy blanks from us as we know they are hard to find in the shops.

Our most popual models are listed here https://www.rivercitytackle.co.uk/blanks

Or you can give us a call.

+44 (0)151 709 5981

info@harrisonrods.co.,uk

Harrison Rods – Our Story

Harrison rods opened it’s doors in Liverpool in 1989. The fishing rod world was starting to realise the potential of carbon fibre and our mission was to use this new material to make the best rods and blanks for the demanding angler.

Although we have grown in the past 30 plus years, the philosophy has not changed, and every rod and blank is still made in the UK.

The Harrison brand has grown largely by word of mouth to be respected all around the world because of quality and performance. We also aim to be the best at customer service. If you buy a Harrison rod you become part of a family and are guaranteed spares and customer support for years to come.

At Harrisons we like to stress our traditional values of craftsmanship but that is only half the story. We also have a programme of research and innovation that keeps us ahead. We led the field in introducing overfit joints when spigots were the fashion. Ballista was the first slim carp blank, and Torrix brought in high modulus carbon with light carbon scrims.

We design and make all the rod blanks ourselves at a time when so many brands have outsourced that skill, and that makes all the difference. We do not make bait, luggage or terminal tackle, we are focussed on making very good fishing rods. We are the rod specilalist!

The picture on the left shows us being honoured with a visit by the then Prince Charles.

Dr. Steve Harrison 2024